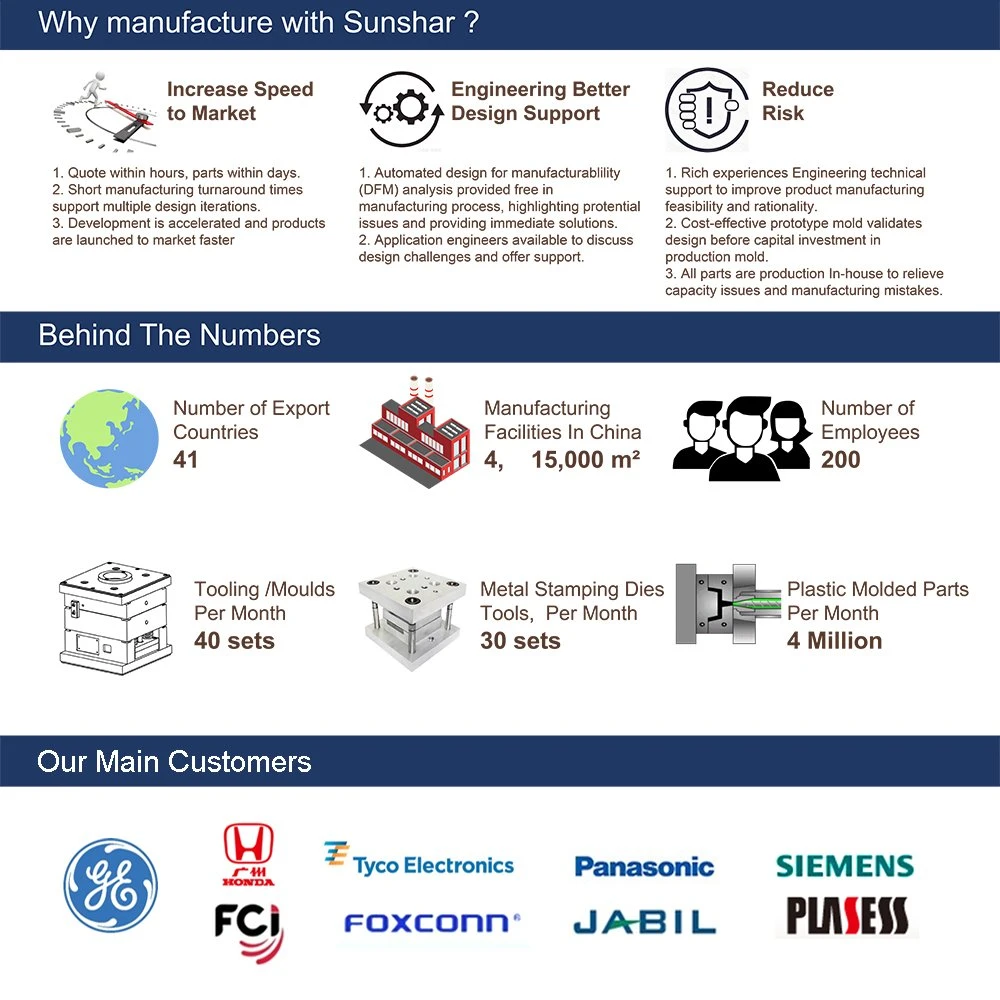

Tipos personalizados de moldagem por injeção de molde de plástico para peças automotivas de conectores eletrônicos

Por que escolher a Sunshar? A Sunshar fornece serviço completo para moldagem por injeção de plástico de alto volume e té

Informação básica

| Modelo Nº. | moldagem por injeção |

| Tipo de plástico | Plástico Termofixo |

| Forma Plástica | Grânulo |

| Método de Moldagem | Moldagem por injeção |

| Material | PA66+30GF |

| Cavidade | Multicavidades |

| Corredor quente | Judo |

| Aço | 1.2344 |

| Máquina de injeção | 60-600 toneladas |

| Aplicativo | Indústrias Eletrônicas, Automóveis, Eletrodomésticos |

| Tempo de Reciclagem | 6s-60s |

| Expediente | 2 turnos 24 horas |

| Processo | Automático |

| Prazo de entrega | 3-15 dias |

| MOQ | Pedido pequeno aceitável |

| Customizar | OEM / ODM |

| Pacote de transporte | Embalagem de papelão |

| Especificação | 80x50x30 |

| Marca comercial | OEM/ODM aceitável |

| Origem | China |

| Código SH | 3926909090 |

| Capacidade de produção | 100 |

A: By express (FedEx, UPS, DHL, TNT, EMS, etc...), By Air or by sea. Q. How do I pay for the order? A. The common payments are T/T (Telegraphic Transfer), western union, PayPal is also available. Q. I have an idea for a new product, but don't know if it can be manufactured. Can you help?A. Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs. Q. What are the advantages to having my parts manufactured locally?A. Sunshar can offer quick reaction times to any changes in specification, batch size or material. We can ship small or large quantities anywhere in Europe overnight to accommodate unforeseen changes in demand. Q. My components have already been developed on CAD. Can you use the drawings?A. Yes! DWG, DXF, IGS, SolidWorks, Pro/E, UG and Catita files can all be used to generate quotes, models and mould/tools - this can save time and money in producing your parts. Q. Can I test my idea/component before committing to mould/tool manufacturing?A. Yes, we can have the CAD drawings to make Computer simulation for designing and functional evaluations. Q. What type of plastic is best for my design/component?A. Materials selection depends on the application range and the environment situation in which it will function. We will be happy to discuss the alternatives and suggest the best material. Q. What type of mould/tool do I need?A. Mold/tools can be either single cavity (one part at a time) or multi-cavities (2,4, 8, 16 up to 64 parts at a time). Single cavity tools are generally used for small volume demand, up to 20,000 parts per year. And multi-cavities tools are for larger demands. We will according to your estimated annual volume demand and recommend the best solution for you. Q. Ok, I've decided to go ahead with my project. How long will it take to get my parts?A. It will take 3-8 weeks to have the mould/tool manufactured. It depends on the part's size, construction complexity and the number of cavities (single or multi). After your final approval for the quality new tool, you can expect the parts delivered within 2-3 days.